The Technology

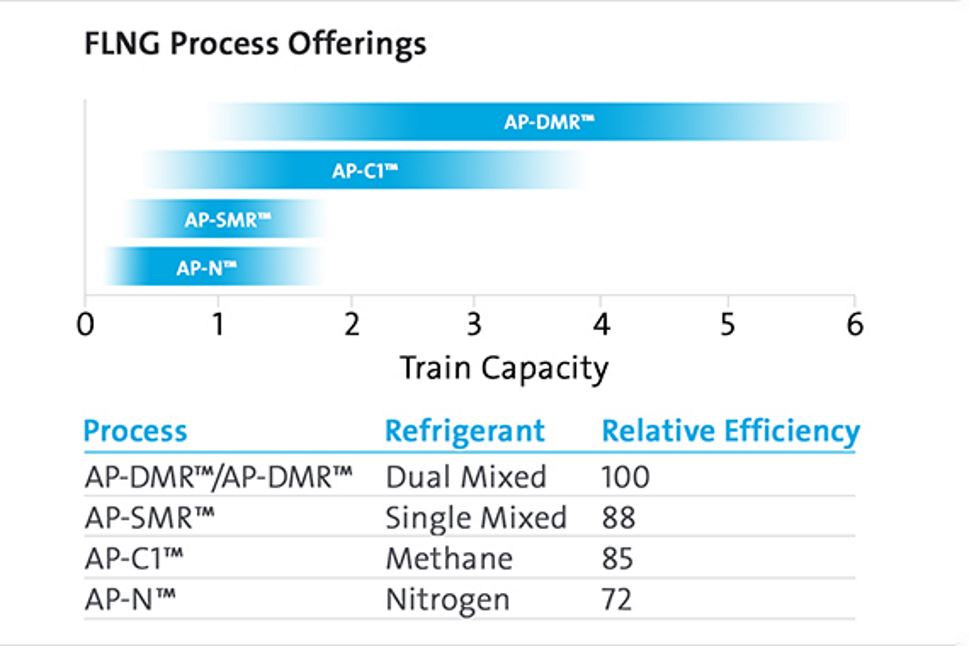

Natural gas liquefaction technologies include the following processes:

- AP-DMR™ (1.0 – 6.0 MTPA)

- AP-N™ (0.1 - 1.8 MTPA)

- AP-SMR™ (0.3 -1.8 MTPA)

- AP-C1™ (0.1 - 4.0 MTPA)

Process guarantees are provided on LNG production and quality, and refrigeration power and quality.

The Equipment

- Coil-wound heat exchangers (CWHEs) for reliable liquefaction with minimal deck space requirement

- Companders, which are highly efficient turbines with a robust skidded design for the offshore FLNG environment

- Cold boxes with plate fin heat exchangers in economizer service, suitable for low thermal transient process conditions (gas cooling gas).

The leading LNG technology and equipment provider

Air Products is the premier global LNG technology, equipment, and services provider. Our unique ability to integrate the liquefaction process design and critical liquefaction equipment leads to an optimization of performance, costs, operability and reliability that has become the benchmark of the LNG industry.

World-class LNG technology adapted for offshore applications