Questions? We've got answers.

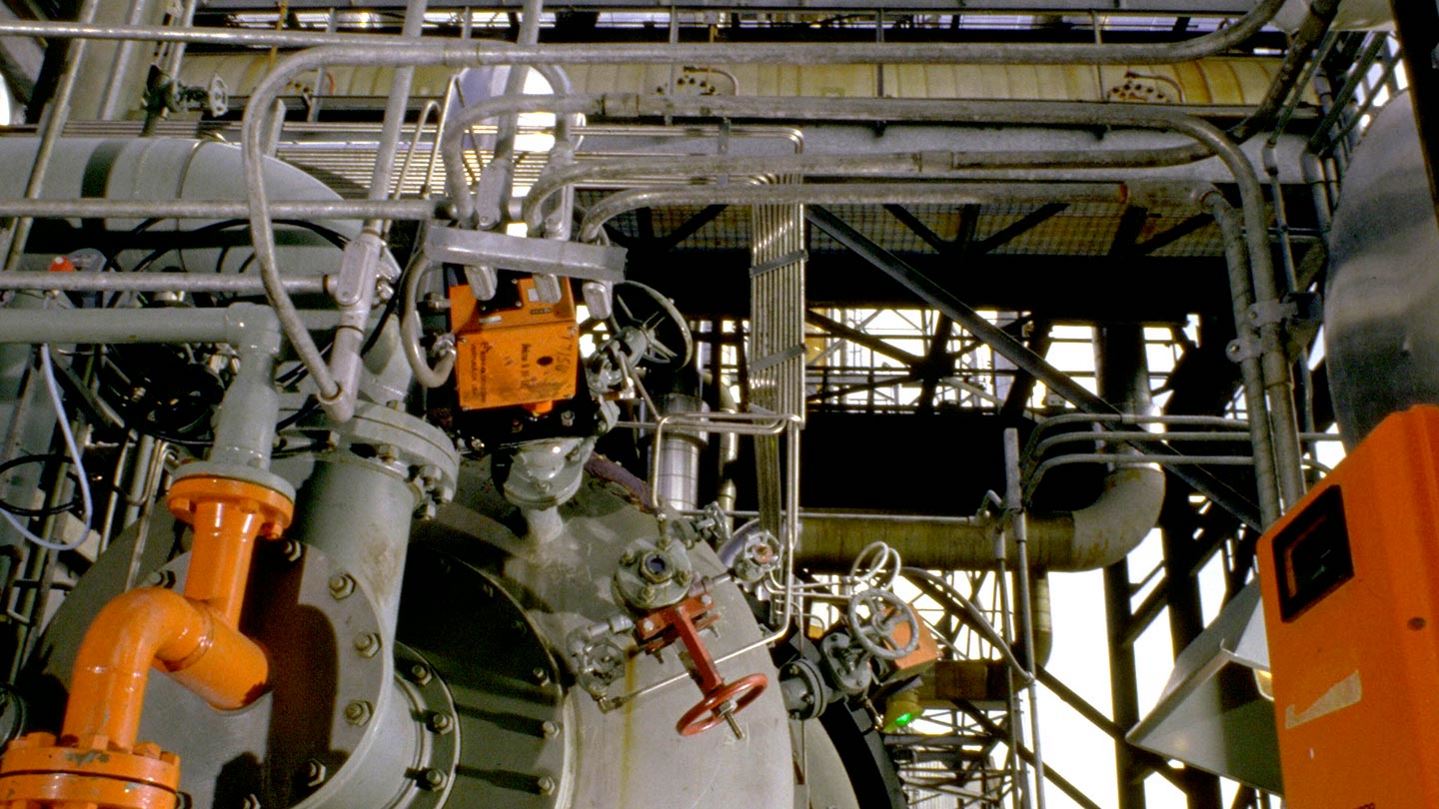

MAXIMIZING REFINERY FLEXIBILITY

Operational flexibility is a must in today's refineries. Sulfur recovery unit oxygen enrichment is a good way to boost capacity in a cost efficient way.

Gases

Air Products gases, typically provided in gaseous and liquid form, enable customers in a wide range of industries to improve their environmental performance, product quality, and productivity.

Oxygen

In addition to its use as a respiratory gas for healthcare applications, its strong oxidizing properties benefit many industries by improving yields, optimizing performance, lowering costs and reducing carbon footprint compared to other fuels.

Bulk Supply

Delivered by truck and stored on your site either as a liquid in cryogenic tanks or as a gas in high-pressure tubes based on your volume, desired pressure, purity level, flow rate, and operating pattern.

On-site Gas Generation

On-site gas generation helps sustainability-minded customers lower their carbon footprint, boost energy efficiency, increase throughput, enhance end product quality, and improve environmental performance.