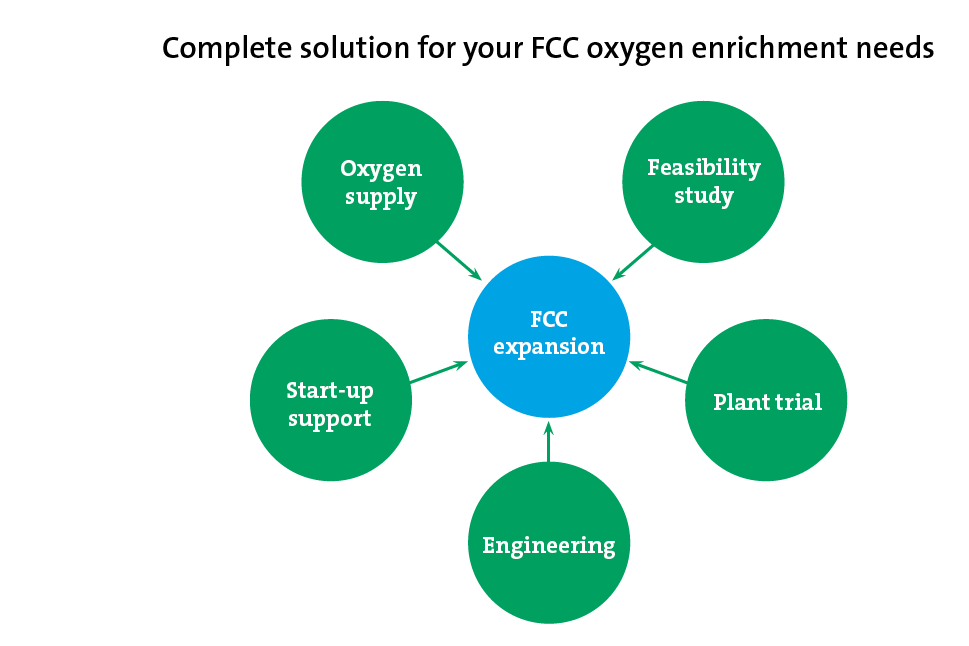

Services for Your FCC Oxygen Enrichment Operation

Air Products can provide the necessary equipment, technology and services:

- Feasibility studies – conduct a technical evaluation of your FCC operation and recommend the level of oxygen required for your desired capacity increase and the best mode of supply

- Engineering – design and build an oxygen flow control system tailored to your operation

- Start-up support – provide oxygen safety training, P&ID review of oxygen flow control system, and hands-on training on how to operate the flow controls

Need help determining if oxygen can help your refining process?

Air Products is always here to help you assess your FCC operation with a technical evaluation to show you the level of oxygen required for your desired capacity increase.