Optimizing Industrial Gases in 3D Metal Printing

In the world of rapid prototyping and production of metal components, it is important to have the proper gas atmosphere to efficiently produce quality parts.

Solutions and Expertise for 3D Printing

- Optimized part treatment via proper gas selection and purity

- Uniform printing as a result of maintaining consistent conditions

- Improved control over chamber management and post-printing heat treatment

- Lower production costs via reliable and cost efficient gas supply

- Easy installation

- Increased safety

How Gases Affect the Quality of Metal Additive Manufacturing?

- Provide inert atmospheres to minimise harmful contaminants

- Allow for a narrow particle size distribution and avoids surface oxidation

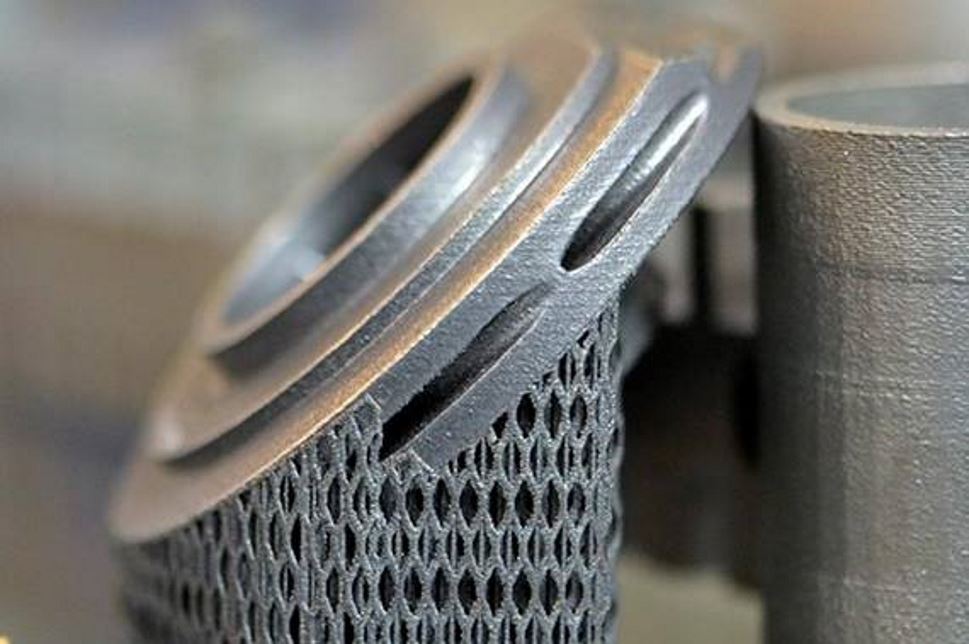

- Reduce stress and improve mechanical properties, with a bright and clean surface finish

- Hot Isostatic Pressing with gases eliminates porosity and voids within the printed part

Get in touch with our technical experts.

Learn more about our shielding gases for 3D printing.

Ask the Expert

Guido Plicht

Commercial Technology Manager - Europe

“How does gas affect the quality of my additive manufacturing process?”

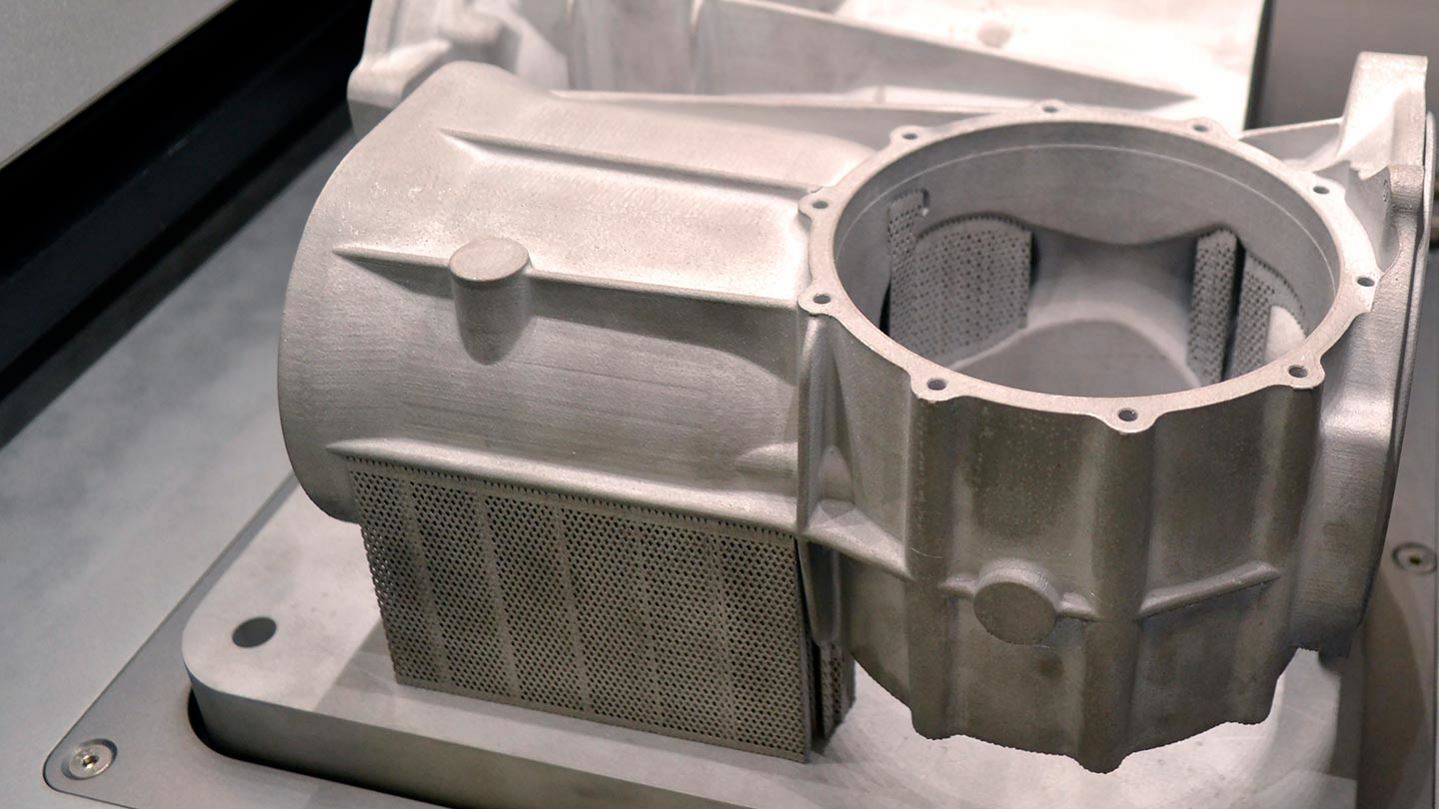

As with other traditional methods of prototyping and manufacturing metal parts, the proper gas atmosphere is critical for producing quality products. Nitrogen and argon are commonly used to provide inert atmospheres during additive manufacturing. It is important to use the correct flow rate and purge duration to avoid deformed parts and ensure a safe production environment. For example, high oxygen content in the atmosphere will result in oxidation of the powder metal leading to poor part quality, clumping in the powder feed, or high porosity in the end product. It will also reduce the amount of recyclable powder for future use. Inerting is also critical for proper management of the combustible dust arising from the powder metal and printing process. Post treatments after printing may require industrial gases, depending on the application.

Gases

Air Products gases, typically provided in gaseous and liquid form, enable customers in a wide range of industries to improve their environmental performance, product quality, and productivity.

Argon

Compressed argon gas and liquid argon in a variety of purities and in various modes of supply around the world thanks to our network of storage and transfill facilities.

Helium

An inert gas for cryogenic, heat transfer, shielding, leak detection, analytical and lifting applications

Nitrogen

Useful as a gas, for its inert properties, and as a liquid for cooling and freezing. Virtually any industry can benefit from its unique properties to improve yields, optimize performance and make operations safer.